PRESENTED FOR THE FIRST TIME AT IFAT:

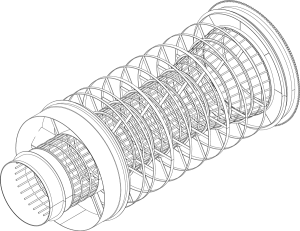

Higher screening capacity in the intermediate grain with the flow-optimized double trommel

Zemmler reacts with a further variant of the double trommel to customers in the wood recycling and EBS sector, who above all find an increased material proportion of 50 % to 80 % in the intermediate grain. A tapered inner drum enables increased throughput and optimum flow of the material in the intermediate grain. Tests have shown that the conical-shaped double drum delivers a considerably higher screening capacity and perfect screening results in the processing of substitute fuels, wood chips, fresh wood or also with shredded EBS material. As with the standard double trommel, wire screens are tensioned on the outer trommel and optionally on the inner trommel. Mesh widths, shape and wire thickness can be selected variably. The flow-optimized double trommel can be installed from type ZEMMELR MULTI SCREEN MS4200.

The patented double trommel is a cheaper and more effective alternative to other conventional screening processes, which often entail high follow-up costs. The processing of compost or topsoil can also be carried out with this double drum without loss of quality or performance, thus maintaining the usual flexibility of the Zemmler brand screening plants.

Company

-

Zemmler Siebanlagen GmbH

Nobelstraße 11

03238 Massen-Niederlausitz - +49 (0) 3531 7906-0

- +49 (0) 3531 7906-41

- info@zemmler.de